Ni paulownia wood, 1900 was born on January 16, Songjiang County, Shanghai, childhood out in the imperialist "concessions" could not bear to see a lot of things to see. When the Japanese invasion of Shanghai, home destroyed in the enemy's shells, the saving from childhood, power of desire. Northern Tianjin University in 1918 obtaining matriculation classes, determined to save the country industry. 1924 cum laude graduate of Mining and Metallurgy, Department of limited financial difficulties, give up the opportunity to study abroad in Shanghai, the public donated patrol bureau office warehouse rather Motors three years later, to any coal mine in Tangshan Kailuan division. Kailuan coal mine in 11 years, he often go to mine, to master the law of the coal seam characteristics and output, flexible use of various mining methods and equipment, effective organization of coal mining. After the outbreak of war, for national survival, he decided to abandonment westward to the development of new mines, coal mines have to build Yiluo Henan, Hunan Enhong mine. After the war the south because of Guangxi, Guangxi Bureau of Mines at the level of resources survey and smelting in the work.

In 1941, afraid of hard Ni paulownia wood safety, border town to the motherland, the world-famous tin production powerhouse - old, hard-working, contributed to the development of Tin's own life. Began his employment as a factory manager selection old, part-time new plant in 1945, and tin Kuangkuang Chang, director of public works in 1946 and was appointed chief engineer of Yunnan Tin Co., Ltd.. In the same year, Ni paulownia wood to go to London, England in the World Tin meeting, and to Canada, the U.S. investigation, joined the American Mining Association. In other countries, see the still in its infancy, several new mineral processing equipment, back to Yunnan Tin Co., Ltd., he was determined to change the old situation behind indigenous beneficiation of mineral processing equipment, a reform process, much has been achieved attracted the attention of international mineral processing industry. However, behind the chaotic social environment, limiting the play of his intelligence. Numerous grim fact that he recognized the KMT's corruption. His sympathy, support progressive forces and the Chinese Communist Party. In December 1949, when Nationalist troops retreat old, he co-Lu Mian Yunnan Tin Co., Ltd. Associate effectively resist the KMT South Eighth Army, twenty-sixth military harassment of Yunnan Tin Company Limited damage, with the underground Communist Party and the People's Liberation Army, intact, Yunnan Tin Co., Ltd., ushered in the Yunnan tin mine life.

After the founding of the People's Republic, Ni paulownia wood with greater enthusiasm into the cause of building socialism. In 1950, Ni paulownia wood Yunnan Tin Corporation, was appointed chief engineer in the mining, mineral processing, smelting technology in both work to accomplish something, especially in the development of gravity beneficiation equipment has made remarkable achievements. In 1958, he was wrongly classified as "rightists", who put him removed from YTC. He was the personal gains, insisted to stay in the YTC complete re-election have not yet done the work on the development of new equipment. 1974 retirement, left the old man, although the heart is still tied YTC, actively and conscientiously to the parties put forward their own ideas and proposals. In 1979, Yunnan Tin Company of Ni paulownia wood to be classified as right wing to give correct the wrong case. 1980 Ni paulownia wood is 80 years old, was invited to participate in Yunnan Tin Company's utilization of the meeting held in Ministry of Metallurgical Industry, the development of Yunnan Tin Company made a number of recommendations. May 20, 1984, Ni paulownia wood died of illness in Jinan.

Mineral processing equipment in China pioneer of modern gravity

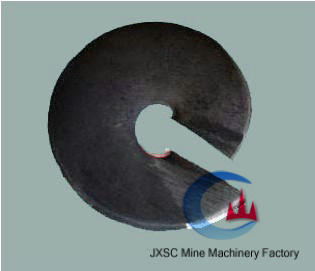

Old history of mining, but the backward technology and equipment, mostly with homemade dressing, use only the mechanical shaker concentrator is imported from Britain. When Ni paulownia wood came here in 1941 as the election Yunnan Tin Co., Ltd. old factory manager at a time when World War II. Japanese troops occupied Hong Kong and Vietnam Hai Phong, the old processing plant Mianlin import?vibrating table?To continuously without loss supplement supply, production will not be seeing the situation. Ni paulownia wood is not satisfied, self-determined development. 1943 in the second half, a successful trial?table concentrator?cement surface, tested in production, the results are satisfactory; but still needed the cement imported from abroad, cement shaker can not promote. He did not despair and continue to develop new shaker. In the development, the Ni paulownia wood Huang adopted the recommendations of skilled workers, the use of lacquer waterproof characteristics, developed shaker lacquer surface. Through trial and modified in 1944, made a successful paint shaker. Shaker lacquer surface hardness, friction and wear are not breathable, immortal loss, separation of fine grade ore is good, technical indicators over imports shaker. Ni paulownia wood lacquer shaker written papers, the importance of the international mineral industry. Thus, instead of imported paint shaker shaker, and long-term production practice constantly improve and perfect. 40 years later, "YTC" brand paint shaker Brazilian exports in 1984 and the United Kingdom.

Old mine homemade dressing, employing bucket of water, workers, regardless of cold and heat, standing in pond operation, not only work hard, fine-grained cassiterite and low recoveries. Ni paulownia wood made with artesian water supply of curtain method. Just when the ineffective trial, reinvent the wheel. After repeated trials, in 1943 the successful development of artesian water supply of the "uniform sub-tank", the role of the use of slope water to achieve the enrichment of selected other purpose than the artificial brick Cao law advanced bucket of water, can improve efficiency and save 80% of workforce .

Old mine ore Shizhong Xi Shi disseminated fine grain size, tin with dense, fine-grained cassiterite ore recovery is one of the key production technologies. Ni paulownia wood With their solid theoretical knowledge and practical experience of long-term, break through the traditional theory of re-election, convection film dressing made of new ideas, and other engineering and technical personnel, workers together in the late 1950s developed a turn-bed, six sludge recycling shaking so fine cassiterite particles re-election of many new devices, so that fine particles in the YTC cassiterite mineral recovery technology has reached international advanced level at the time. His design, development and continuous improvement of the water analysis device, pulp enhanced gravity concentrator meter of the production technology management played an important role. His theory of gravity beneficiation flow membrane, have a profound impact in beneficiation industry, respected by the academic community, has become a prestigious dressing experts.

Tin industrial base of the "boss"

Ni paulownia wood knowledgeable, proficient not only theory and technology of mineral processing and mining, smelting, machinery, construction is also very good at it. In 1950, he was appointed chief engineer for the Yunnan Tin Corporation, after enthusiastically take on the burden of building a new technology YTC. To meet the national need for the construction of the tin, a wealth of development resources into the development of Yunnan Tin tin old plant produced the key. After argument, decided to build a frame length of 16 km two-lane cable transport ore, tin ore the old plant shipped to Datun concentrator for washing. Central Ministry of Heavy Industry Nonferrous Metals Industry Administration in the country for no one volunteered to design the case, presided over by the Ni paulownia wood design and construction of command. YTC's scientific and technical personnel were not designed cable experience, Ni paulownia wood, I have never seen such a big load cable. For the design of cable, he and Li Fengtong, Pi chapter and other mountains, site investigation. The end of 1951 the design is completed, start in January 1952, completed 1953 test. In the testing process, to resolve the issue out of the bucket, the total Ni rolled up bedding, living for a month to move mine a whole. He asked his wife to his meal, his focus on observation, measurement, thinking, calculation, and finally to obtain the necessary data to solve the problem out fighting. This mine was China's longest cableway, to 90 years is still running, for the construction of our cable accumulated experience to develop a pool of talent. Same period, he also presided over the design and built a modern day processing 1,500 tons of tin concentrator - Datun oxidized ore dressing plant and part of the renovation and expansion project for the restoration, development and training of Yunnan Tin production technology has made important contributions.

Mining front and never retired, "soldiers"

Ni Tong mining wood love, love the YTC, with a high degree of professionalism and responsibility. In 1958, he was wrongly classified as a "rightist", punished by dismissal pay cut and proposed to him transferred. Although he was in difficult circumstances, but the personal gains, still insist to stay in Yunnan Tin to complete the re-election have not yet finished work on the development of new equipment. Yunnan Tin Company to meet his demands, he fully energy into mineral research. 1958 to 1960, he completed "YTC Flip", "20-layer bed turning" and "On the hydrocyclone used in several problems in the field of study" and six papers, the technical equipment used in production actually described and summarized. In 1960, Ni paulownia wood, the "rightist" After take off the hat, was appointed chief engineer of the Yunnan Tin-center trial. He offered to bed turn-based processing 600 tons of sludge on plant-building program. In 1963, Ni paulownia wood chair with a chute (Flip) and shaking the joint, poor sorting Donganshan hematite experiments, to feed grade 34.5% concentrate grade 60.58%, 88.05% recovery indicators, than the Soviet Union's full flotation and magnetic separation processes all the indicators is slightly higher for the poor hematite Donganshan lay the foundation for re-election.

In 1974, Ni paulownia wood retirement, with his son to settle in Jinan, Shandong. Have left the tin man, heart still maintain the mine. In 1974, he wrote to the Yunnan Tin Corporation, pointed out that the four production problems and their solutions. In 1975, he proposed to the Ministry of Metallurgical Industry vibration red iron ore concentrator pilot program to address the problem of poor iron ore beneficiation. In 1976, he learned that old drought, Yunnan Tin Company for nine consecutive times to write, to propose solutions of water ways. May 15, 1978, he gave the Ministry of Metallurgy Office of Science and Technology letter comrades, once again made using a vibrating sorting hematite mineral processing machine, "take off the red ore beneficiation technology," he wrote: " I was nearly ten days, and suffering from coronary heart disease, but also hoping to force out a little before the end of life take this off for a great four modernizations made a modest contribution. "At the same time, he gave the company responsible comrades of the YTC proposed development of vibration concentrator problem, Yunnan Tin Company personnel were studied. He also raised the "stick-generation ball" to address the recommendations of crushed ore over by the company's attention and use. In 1980, he traveled regardless of the frail and elderly, were invited to participate in Yunnan Tin Company's utilization of the meeting held in Ministry of Metallurgical Industry, to the Yunnan Tin Corporation made many good suggestions.

Ni paulownia wood production and construction concern YTC, YTC is more concerned about the growth of technical personnel. Back in the 1950s, he worked tirelessly to learn not only their own, personal counseling and training the younger generation. Under his care, some people have been self-taught, grew from a junior high school senior engineer for the dressing. After retirement, he continued to write to inform their colleagues, themselves from the old society, seen and heard strong feelings, Chinese people have stood up in 1949, but industrial and agricultural production developed, only a half points, but not all station, pay close attention to colleagues Love limited to mining science and technology rapidly developed. He was a middle-aged engineers and technicians to the letter affectionately wrote: "I came in 1941, YTC, you feel old this great non-ferrous metal ore, is the motherland of a large treasure." "No one wanted a strong country. it must be powerful four modernizations. to achieving the four modernizations, we all bear a heavy responsibility and hard, I can not put this responsibility on the edge of death. "YTC's advice to his comrades technical problems, he eleven to be technical guidance through correspondence. In his last breath of life, also left behind a letter to an engineer of the Yunnan Tin Company has not yet finished writing the letter. He dedicated his life to the motherland, mining, expressed his utter devotion to the socialist motherland.

2011年9月26日星期一

Overview of various gravity concentrators methods

Iron: 1, ore crushing; 2, grinding crafts; 3, sorting techniques; 4, sintering technology;

Manganese: mechanical options (including mineral processing, gravity concentrators, re-election, high intensity magnetic separation and flotation), and assistant set fire method, chemical processing method.

Chrome: The jump titanium machine, shaker,; gravity concentrator, centrifugal concentrator and belt chute sorting, and sorting do not over water power shaking mine.

Vanadium titanium magnetite: is it a period of grinding, a coarse, a fine, sweeping away the magnetic separation process, after the magnetic magnetite concentrate selected for the magnetic sound.

Copper: flotation, magnetic separation, or re-election and other methods such as hydrometallurgy.

Lead and Zinc: General magnetic - floating, heavy - floating, heavy - Magnetic - floating and other joint beneficiation.

Aluminum: general hand-selected.

Nickel: 1, flotation; 2, the use of crushing, screening and other processes remove the differentiation of pre-nickel low weakly large bedrock.

Cobalt: 1, flotation; 2, the use of crushing, screening and other processes remove the differentiation of pre-nickel low weakly large bedrock.

W: tungsten ore by ore type is divided into black and white tungsten tungsten. Beneficiation methods are hand-selected, re-election, flotation, magnetic separation, and electrostatic and other methods.

Tin: for the gravity beneficiation beneficiation, flotation process.

Molybdenum: mainly flotation.

Mercury: a hand-selected, re-election and flotation, which is widely used and most effective flotation.

Antimony: There are hand-selected, re-election, flotation and other methods.

Platinum group: 1, reasonable goals, use of appropriate cyclone classification; 2, the recovery rate.

Gold: gold in the ore were very low, the need to extract gold ore crushing and grinding and dressing methods used to separate the gold. Mainly re-election and flotation.

Silver: 1, flotation; 2, a single flotation and floating - gravity separation, flotation and cyanidation of the joint process, in which the flotation is most important.

Niobium tantalum lithium beryllium: hand-sorting method, flotation, chemical or chemical - flotation combined method, heated election law, election law radioactive, particles floating processing method.

Strontium: tungsten ore celestite society most commonly used method, the most common structure to the process of jigging - shaker as the main process.

Rare earth metals: general use of magnetic separation, flotation concentrate containing rare earth oxides to be about 60%.

vibration tables is a commonly used laboratory equipment

vibration tables is a commonly used laboratory equipment, biological equipment is widely used for high temperature and oscillation frequency requirements of bacterial culture, fermentation, hybridization, biochemical reactions and enzymes and tissue research. Shake the liquid commonly used laboratory, microbes, bacteria and cell culture.

One Category:

(1) gold tables at room temperature:

Small gold tables, Shaker, Shaker in which there are: the transfer of Shaker, back and forth swing oscillator, the oscillation reciprocating shaker, multi-speed reciprocating shaker, rotary oscillator, Alice Plate Shaker, Shaker wave, multi-purpose rotary shaker, shaker and other circular-type shock

(2) constant temperatureshake table:

Desktop constant temperature oscillator, oscillator heating, refrigeration oscillator shaking, constant temperature air bath shake table,

Water bath shaker, digital thermostat shaker, digital water bath shaker, large amplitude high-capacity (light

Photo) oscillator shaker, large double-DA-temperature shaker frequency, new precision economy temperature

Shaker, etc.

(3) training shaker:

Shaking shaking, the whole temperature culture shaker, shaker incubation, cell culture shaker,

LCD temperature (desktop) to develop shaker, incubation shaker frequency, oscillation shaking culture

Boxes, horizontal shaker incubator,

(4) intelligent shaker:

Intelligent control of a small desk shaker, intelligent temperature control precision shaker small desktop, smart

High-precision large, full temperature control thermostat shaker light, intelligent control precision constant temperature shaker, intellectual

Double-precision thermostat to control the shaker

(5) Other:

Micro-oscillator shaker, shaker powder dissolver, syphilis rotating instrument shaker, shake bottle machine double

Shaker, Kahn shaker, small oscillations microplate shaker, shaker large amplitude mass oscillator,

Ordinary large-capacity reciprocating shaker, large amplitude high-capacity (light) oscillator shaker, three

Shaker, double-shaking, two-dimensional shaking, three-dimensional shaking, shaking generic, universal shaking and so on.

Constant temperature shaker accessories:

One Category:

(1) gold tables at room temperature:

Small gold tables, Shaker, Shaker in which there are: the transfer of Shaker, back and forth swing oscillator, the oscillation reciprocating shaker, multi-speed reciprocating shaker, rotary oscillator, Alice Plate Shaker, Shaker wave, multi-purpose rotary shaker, shaker and other circular-type shock

(2) constant temperatureshake table:

Desktop constant temperature oscillator, oscillator heating, refrigeration oscillator shaking, constant temperature air bath shake table,

Water bath shaker, digital thermostat shaker, digital water bath shaker, large amplitude high-capacity (light

Photo) oscillator shaker, large double-DA-temperature shaker frequency, new precision economy temperature

Shaker, etc.

(3) training shaker:

Shaking shaking, the whole temperature culture shaker, shaker incubation, cell culture shaker,

LCD temperature (desktop) to develop shaker, incubation shaker frequency, oscillation shaking culture

Boxes, horizontal shaker incubator,

(4) intelligent shaker:

Intelligent control of a small desk shaker, intelligent temperature control precision shaker small desktop, smart

High-precision large, full temperature control thermostat shaker light, intelligent control precision constant temperature shaker, intellectual

Double-precision thermostat to control the shaker

(5) Other:

Micro-oscillator shaker, shaker powder dissolver, syphilis rotating instrument shaker, shake bottle machine double

Shaker, Kahn shaker, small oscillations microplate shaker, shaker large amplitude mass oscillator,

Ordinary large-capacity reciprocating shaker, large amplitude high-capacity (light) oscillator shaker, three

Shaker, double-shaking, two-dimensional shaking, three-dimensional shaking, shaking generic, universal shaking and so on.

Constant temperature shaker accessories:

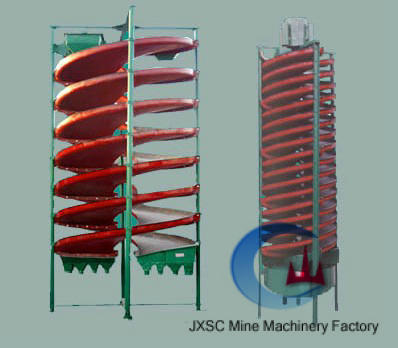

spiral separator use and principle

spiral separator use and principle: the spiral chute erected, vertical alignment, or wood with a metal frame fixed in the right place, by the sand pump the ore to the screw on the top two at the inlet, adding additional water, adjust mine paddle concentration of natural mineral paddle down from the high swirling flow in a rotating inclined to produce a centrifugal force of inertia to the proportion of ore, size, shape differences, gravity and centrifugal force through the cyclone effect separated from the ore and sand, ore concentrate into a bucket with a pipe connection, the tailings flow into the tailings pipeline received a bucket with sand pool, sand pump and then discharged to complete the whole process of dressing.

Spiral chute (FRP Spiral Groove) is mainly connected by the spiral slice spiral groove into the composition. Spiral steel sheet of glass (glass fiber reinforced plastics).

spiral concentrators (FRP Spiral Groove) for sorting of fine iron ore, ilmenite, chromite, pyrite, tin, tantalum and niobium ore, gold, coal, monazite, rutile, zircon, rare earth mine and has sufficient density difference of the other metals, non-metallic minerals.

spiral concentration (FRP Spiral Groove) has a small footprint, ease of operation, mineral processing and stability, reasonable structure, simple installation, sub-ore clear, large capacity, high efficiency characteristics. It also has a moisture-proof, rust, corrosion resistance, adaptability, noise, etc.

Spiral chute (FRP Spiral Groove) is mainly connected by the spiral slice spiral groove into the composition. Spiral steel sheet of glass (glass fiber reinforced plastics).

spiral concentrators (FRP Spiral Groove) for sorting of fine iron ore, ilmenite, chromite, pyrite, tin, tantalum and niobium ore, gold, coal, monazite, rutile, zircon, rare earth mine and has sufficient density difference of the other metals, non-metallic minerals.

spiral concentration (FRP Spiral Groove) has a small footprint, ease of operation, mineral processing and stability, reasonable structure, simple installation, sub-ore clear, large capacity, high efficiency characteristics. It also has a moisture-proof, rust, corrosion resistance, adaptability, noise, etc.

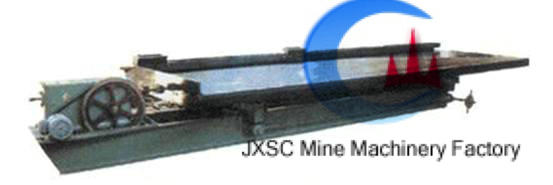

Table concentrator is used for

table concentrator can be used for roughing, selection, selection of different sweep operations, sorting coarse sand (2-0.5mm), fine sand (0.5-0.074mm), sludge (-0.074) and different grain size. Also be used for sorting iron, manganese ore and coal. When dealing with tungsten, tin and other ores, the shaking of the effective recovery of particle size range of 2-0.22 mm.

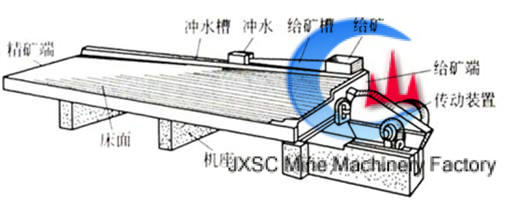

Shaker works:

table concentrator motor driven by the belt drive pulley so that the crankshaft rotating rocker shaker equipment along for the upper and lower motor, joystick downward movement, in a tilt to the counter of the mineral complex material through the mine shafts come in, shake the impact of the water tank to provide horizontal bed, so while the vibration, while washing, specific gravity and particle size, density of different minerals in different directions along the bed from the shaker concentrate mouth, and mouth out of tailings directly to form high-quality Concentrate! As the replacement of mining shaker, shaker in mining capacity, and precision are greatly improved!

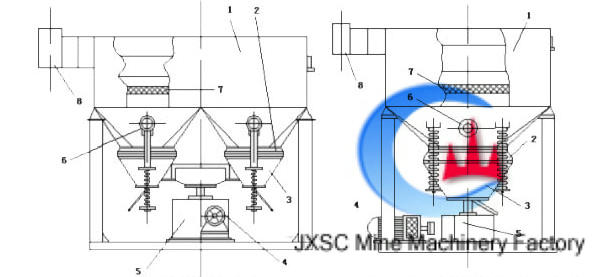

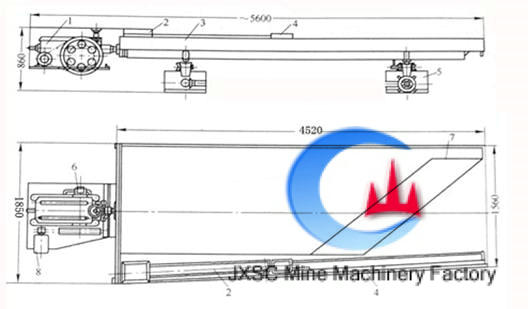

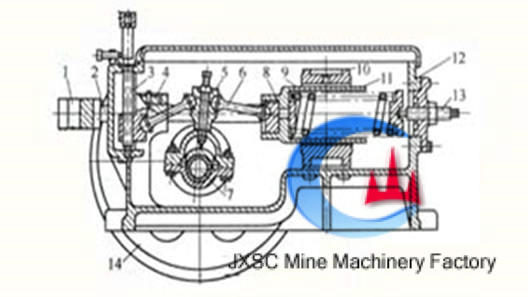

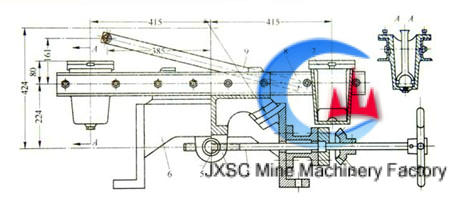

vibrating table the main structure:

Mainly by the bed shaking, motor, adjust slope control, bed, mine shafts, tanks, and to re-lubrication system of eight-part shaker, the bed of the vertical reciprocating motion by crank and connecting rod type transmission mechanism to achieved. Shaker motor through the belt drive pulley to drive the big stick along for the crankshaft rotation, the next movement, downward movement of the joystick, push the rear axle and the bracket backwards reciprocating rod, the spring is compressed by the bed linkage rod connected to the seat and back and forth, so this time also to make the bed for the back movement, when the joystick upward movement, as done by the spring force to promote, along with the forward movement of the bed.

vibrating table how to operate:

1, the material in the bed and sub-products with the interception. In the operating conditions are suitable, the material in the bed shaking zonation is obvious, in accordance with the requirements of the product is to intercept the target separation, can be divided into 2 to 4 kinds of products. Generally in the mine re-processing. When operating conditions change, the zoning situation will change, this time the location of access must also be adjusted accordingly, to ensure the stability of sorting index. Therefore, shaking the operator to remain at their posts, with close surveillance of the situation points at any time make the necessary adjustments.

2, in addition, also with horizontal shaking water lateral slope match the size, makes a good sorting results.

3, rinse water, the size should be appropriate. Rinse water, including mineral water and wash water to two parts, rinse water should be evenly distributed in the bed surface, the size should be appropriate. Wash water concentrate grade large increase, but the recovery decreased. Generally coarse-grained materials or selection process, the rinse water to be bigger.

4, appropriate to the ore concentration. Concentration of the ore dressing shaker is to ensure that the pulp along the bed can have full mobility and can be layered, immersion depth to mineral particles. General sorting, the coarse sand to mine the concentration of 20%. 30% fine ore concentration of 15% to 25%. Most of the water to the mine tailings along with horizontal shed, fine mud easily be washed away, resulting in the loss of fine metallic minerals.

5, suitable for the stroke and of stroke. Stroke and of stroke and the appropriate value of the main selected particle size, load and mineral density of the shaker. When dealing with large size, bed thickness of the material, the use of a large stroke and small red times; when dealing with fine sand and slime, then the opposite should be washed with small stroke and large times. When the load bed of a large density increase or selection of materials for the appropriate use of a larger stroke and of stroke. Stroke, strokes per the appropriate values ??to be examined carefully in practice to determine.

Shaker works:

table concentrator motor driven by the belt drive pulley so that the crankshaft rotating rocker shaker equipment along for the upper and lower motor, joystick downward movement, in a tilt to the counter of the mineral complex material through the mine shafts come in, shake the impact of the water tank to provide horizontal bed, so while the vibration, while washing, specific gravity and particle size, density of different minerals in different directions along the bed from the shaker concentrate mouth, and mouth out of tailings directly to form high-quality Concentrate! As the replacement of mining shaker, shaker in mining capacity, and precision are greatly improved!

vibrating table the main structure:

Mainly by the bed shaking, motor, adjust slope control, bed, mine shafts, tanks, and to re-lubrication system of eight-part shaker, the bed of the vertical reciprocating motion by crank and connecting rod type transmission mechanism to achieved. Shaker motor through the belt drive pulley to drive the big stick along for the crankshaft rotation, the next movement, downward movement of the joystick, push the rear axle and the bracket backwards reciprocating rod, the spring is compressed by the bed linkage rod connected to the seat and back and forth, so this time also to make the bed for the back movement, when the joystick upward movement, as done by the spring force to promote, along with the forward movement of the bed.

vibrating table how to operate:

1, the material in the bed and sub-products with the interception. In the operating conditions are suitable, the material in the bed shaking zonation is obvious, in accordance with the requirements of the product is to intercept the target separation, can be divided into 2 to 4 kinds of products. Generally in the mine re-processing. When operating conditions change, the zoning situation will change, this time the location of access must also be adjusted accordingly, to ensure the stability of sorting index. Therefore, shaking the operator to remain at their posts, with close surveillance of the situation points at any time make the necessary adjustments.

2, in addition, also with horizontal shaking water lateral slope match the size, makes a good sorting results.

3, rinse water, the size should be appropriate. Rinse water, including mineral water and wash water to two parts, rinse water should be evenly distributed in the bed surface, the size should be appropriate. Wash water concentrate grade large increase, but the recovery decreased. Generally coarse-grained materials or selection process, the rinse water to be bigger.

4, appropriate to the ore concentration. Concentration of the ore dressing shaker is to ensure that the pulp along the bed can have full mobility and can be layered, immersion depth to mineral particles. General sorting, the coarse sand to mine the concentration of 20%. 30% fine ore concentration of 15% to 25%. Most of the water to the mine tailings along with horizontal shed, fine mud easily be washed away, resulting in the loss of fine metallic minerals.

5, suitable for the stroke and of stroke. Stroke and of stroke and the appropriate value of the main selected particle size, load and mineral density of the shaker. When dealing with large size, bed thickness of the material, the use of a large stroke and small red times; when dealing with fine sand and slime, then the opposite should be washed with small stroke and large times. When the load bed of a large density increase or selection of materials for the appropriate use of a larger stroke and of stroke. Stroke, strokes per the appropriate values ??to be examined carefully in practice to determine.

One kind of vibration tables for sorting

One kind of vibration tables for sorting of fine material gravity concentration equipment, widely used in sorting tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, iron, manganese, titanium-iron and coal. I plant shake table has a long history, and continue to develop innovative, straight from the original bed shaker Qu Bo on the basis of the development to single-bed shaker (1970s); to bed shaker two-Qu Bo (on the 1990s), so that the amount of processing shaker, recovery and enrichment ratio has improved greatly.

China mainly grown in Jiangxi fortress, the 1970s began to start production in Jiangxi fortress shaker, shaker has now become a major global producer.

Main Categories

Processing machinery series equipment | stone crushing series of complete sets of equipment | Grinder machine equipment series | sand making series of complete sets of equipment | Pastes Series equipment. The main mineral processing equipment includes: ball mill, energy saving ball mill, ball mill energy efficient, high efficiency ball mill, cement mill, dry mill, wet ball mill, ball mill drum, select iron ball mill, high-energy ball mill, roller mill, stirred ball mill, mining ball mill, jaw crusher, jaw crusher, magnetic separator, permanent magnetic drum magnetic separator, dry magnetic separator, wet magnetic separator, magnetic separation equipment, rotary kiln, rotary drum dryer, dryers, dryer production process, industrial drying machine, drying machine heat transfer in vitro, vibrating feeder, vibrating feeder, electromagnetic feeder, vibrating screen, circular vibrating screen, vibrating screen, classifier, spiral grading machine, grading equipment, flotation machine, flotation equipment, spiral chute, efficient concentrator, high frequency screen, high quality screen, the finished product screen, screening equipment, screening equipment, shaker, and disc granulator a variety of mining mineral processing equipment. In addition, the company is able to provide project design, process design, design and manufacture of standard and nonstandard.

6-S-type shaker is a physical processing equipment, it is mainly used for sorting gold, silver, lead, zinc, tantalum, niobium, tin and other metals and precious metal ore.

The main structure

Mainly by the gold tables, motor, adjust slope control, bed, mine shafts, tanks, and to re-lubrication system of eight components of the vertical bed

Reciprocating motion through the crank-link transmission to achieve. Motor through a belt drive pulley to drive the big stick along for the crankshaft rotation, the next movement, downward movement of the joystick, push the rear axle and the bracket backwards reciprocating rod, the spring is compressed bed seat and back and forth through the linkage rod connected, so this time also to make the bed for the back movement, when the joystick upward movement, as done by the spring force to promote, along with the forward movement of the bed.

Specification Type

There is also a shaker in the laboratory using biological shaker, in the laboratory to develop micro-organisms or through the shaken cells, cultured cells need to be carbon dioxide control. More generally for the suspension shaking culture cells can be used. Compared to traditional training methods, shaker culture out of the cell activity higher density / volume even more.

Cell culture shaking a functional cell culture shaker requires temperature control, humidity control, carbon dioxide control, light control, and high-performance insulation and sealing function can be sterilized

Sterilization function.

China mainly grown in Jiangxi fortress, the 1970s began to start production in Jiangxi fortress shaker, shaker has now become a major global producer.

Main Categories

Processing machinery series equipment | stone crushing series of complete sets of equipment | Grinder machine equipment series | sand making series of complete sets of equipment | Pastes Series equipment. The main mineral processing equipment includes: ball mill, energy saving ball mill, ball mill energy efficient, high efficiency ball mill, cement mill, dry mill, wet ball mill, ball mill drum, select iron ball mill, high-energy ball mill, roller mill, stirred ball mill, mining ball mill, jaw crusher, jaw crusher, magnetic separator, permanent magnetic drum magnetic separator, dry magnetic separator, wet magnetic separator, magnetic separation equipment, rotary kiln, rotary drum dryer, dryers, dryer production process, industrial drying machine, drying machine heat transfer in vitro, vibrating feeder, vibrating feeder, electromagnetic feeder, vibrating screen, circular vibrating screen, vibrating screen, classifier, spiral grading machine, grading equipment, flotation machine, flotation equipment, spiral chute, efficient concentrator, high frequency screen, high quality screen, the finished product screen, screening equipment, screening equipment, shaker, and disc granulator a variety of mining mineral processing equipment. In addition, the company is able to provide project design, process design, design and manufacture of standard and nonstandard.

6-S-type shaker is a physical processing equipment, it is mainly used for sorting gold, silver, lead, zinc, tantalum, niobium, tin and other metals and precious metal ore.

The main structure

Mainly by the gold tables, motor, adjust slope control, bed, mine shafts, tanks, and to re-lubrication system of eight components of the vertical bed

Reciprocating motion through the crank-link transmission to achieve. Motor through a belt drive pulley to drive the big stick along for the crankshaft rotation, the next movement, downward movement of the joystick, push the rear axle and the bracket backwards reciprocating rod, the spring is compressed bed seat and back and forth through the linkage rod connected, so this time also to make the bed for the back movement, when the joystick upward movement, as done by the spring force to promote, along with the forward movement of the bed.

Specification Type

There is also a shaker in the laboratory using biological shaker, in the laboratory to develop micro-organisms or through the shaken cells, cultured cells need to be carbon dioxide control. More generally for the suspension shaking culture cells can be used. Compared to traditional training methods, shaker culture out of the cell activity higher density / volume even more.

Cell culture shaking a functional cell culture shaker requires temperature control, humidity control, carbon dioxide control, light control, and high-performance insulation and sealing function can be sterilized

Sterilization function.

The application of gravity concentrators method

The application of gravity concentrators method

Be useful for re-election deal with the gangue minerals with large density difference between the ore or other raw materials it is dealing with coarse, medium-and fine-grained (generally limit is greater than 25 mm, 25 "2 mm, 2 ~ O .1 mm) ore effective method in dealing with fine mineral mud (less than 0.1 mm) is not efficient, modern and effective flow of film processing equipment can be recycled to the 20-30 micron grain size, gravity concentrators centrifugal concentrator can go to 10 microns. In recent years, non-metallic mineral processing industry has also been re-elected in the development, stone crushing production line, mainly for treatment of asbestos, diamond, kaolin, apatite, pyrite and other minerals in the sorting of copper, lead, zinc, antimony, mercury sulfide ore flotation plant. are often used method for re-election pre-ore in the primary election process often re-election to form a coalition with other mineral processing procedures, in order to advance the state election in coarse concentrates or tailings. This will help reduce production costs and reduce metal loss when dealing with a variety of methods to choose from the ore, the re-election law is always a priority. re-election to the fluid medium for a certain, hammer crusher China Academy of Sciences: 0215 years in China can be expected to achieve a manned lunar landing techniques, the use of media, usually water,gravity concentrator air or when there are heavy media (heavy weight solution or suspension.) media in the sorting equipment in a certain way movement of minerals particles by the media the role of buoyancy and hydrodynamic loose. and then to press the density (and sometimes by size) poor stratification. stratification processes influence the nature of mineral particles is its density, size and shape of the more minor factors.

Edit this paragraph the law of gravity beneficiation process method

Media campaign by the form and purpose of operations, process re-election there are several ways: (1) classification (2) heavy media beneficiation (3) jig beneficiation (4) shaker dressing (5) ore chute (6) spiral concentrator (7) centrifugal dressing (8) Wind dressing (9) washing grading and washing operations are separated according to size, before the ore used in selected preparations. all other sorting process is a substantial operations, but also Benpian described below will be the content of gates. ore ease of re-election depends on the density difference between the minerals, according to E re-election of optional criteria to judge.

Be useful for re-election deal with the gangue minerals with large density difference between the ore or other raw materials it is dealing with coarse, medium-and fine-grained (generally limit is greater than 25 mm, 25 "2 mm, 2 ~ O .1 mm) ore effective method in dealing with fine mineral mud (less than 0.1 mm) is not efficient, modern and effective flow of film processing equipment can be recycled to the 20-30 micron grain size, gravity concentrators centrifugal concentrator can go to 10 microns. In recent years, non-metallic mineral processing industry has also been re-elected in the development, stone crushing production line, mainly for treatment of asbestos, diamond, kaolin, apatite, pyrite and other minerals in the sorting of copper, lead, zinc, antimony, mercury sulfide ore flotation plant. are often used method for re-election pre-ore in the primary election process often re-election to form a coalition with other mineral processing procedures, in order to advance the state election in coarse concentrates or tailings. This will help reduce production costs and reduce metal loss when dealing with a variety of methods to choose from the ore, the re-election law is always a priority. re-election to the fluid medium for a certain, hammer crusher China Academy of Sciences: 0215 years in China can be expected to achieve a manned lunar landing techniques, the use of media, usually water,gravity concentrator air or when there are heavy media (heavy weight solution or suspension.) media in the sorting equipment in a certain way movement of minerals particles by the media the role of buoyancy and hydrodynamic loose. and then to press the density (and sometimes by size) poor stratification. stratification processes influence the nature of mineral particles is its density, size and shape of the more minor factors.

Edit this paragraph the law of gravity beneficiation process method

Media campaign by the form and purpose of operations, process re-election there are several ways: (1) classification (2) heavy media beneficiation (3) jig beneficiation (4) shaker dressing (5) ore chute (6) spiral concentrator (7) centrifugal dressing (8) Wind dressing (9) washing grading and washing operations are separated according to size, before the ore used in selected preparations. all other sorting process is a substantial operations, but also Benpian described below will be the content of gates. ore ease of re-election depends on the density difference between the minerals, according to E re-election of optional criteria to judge.

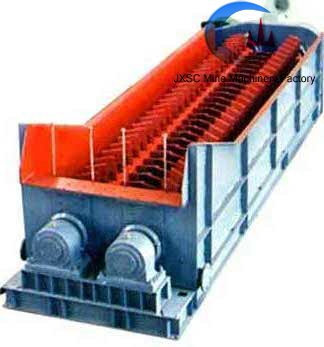

spiral concentrators are high weir single helix

Mineral spiral separator is one of the devices, spiral classifier with different proportion of solid particles, which precipitate in the liquid at different speeds in principle, a device for mechanical grading. Feed mill can grind powder level in the filter, then screw the thick film material using rotary vane screw mill feed, to filter out the fine material discharged from the overflow pipe. Spiral classifier referred to as the grading machine. There are high-grading machine weir single helix and double helix, single helix and the sinking of the double helix four kinds of classifiers.

spiral concentrators are high weir single helix and double helix, low weir single helix and double helix, single helix and the sinking of the double helix of several classifiers, the use of a low weir is small, mainly high weir style and immersed.

Mineral spiral classifier is one of the devices, spiral classifier with different proportion of solid particles, which precipitate in the liquid at different speeds in principle, a device for mechanical grading. Feed mill can grind powder level in the filter, then screw the thick film material using rotary vane screw mill feed, to filter out the fine material discharged from the overflow pipe. Spiral classifier referred to as the grading machine. There are high-grading machine weir single helix and double helix, single helix and the sinking of the double helix four kinds of classifiers.

Classifier widely used in the processing plant in closed circuits with ball dubbed sub-process diversion mineral sands, or in a gravity concentrator in the spiral classifier to grade ore and fine clay, and metal beneficiation process for particles of slurry grading, washing and de-mining operations in the mud, dehydration and other operations. The machine has a simple structure, reliable, easy to operate.

Grading machine is by means of solid particles of different sizes, different weight, thus the settling velocity of different liquids in principle, fine mineral particles floating in the water to overflow out of coarse mineral particles sink to bottom. Discharged by the screw into the upper part, to a hierarchical classification of mechanical equipment within the mill can grind the material powder level in the filter, then screw the thick film material using rotary vane screw mill feed, to filter out the fine material discharged from the overflow pipe. The machine uses the base channel, welded steel plate body. Screw axis into the head, shaft, using cast iron sleeve, wear durability, improved sub-unit of electric and manual.

Spiral classifier works:

Spiral classifier is by means of solid particles of different sizes, different weight, thus the settling velocity of different liquids in principle, fine mineral particles floating in the water to overflow out of coarse mineral particles sink to bottom. Discharged by the screw into the upper part, to a hierarchical classification of mechanical equipment within the mill can grind the material powder level in the filter, then screw the thick film material using rotary vane screw mill feed, to filter out the fine material discharged from the overflow pipe. The machine uses the base channel, welded steel plate body. Screw axis into the head, shaft, using cast iron sleeve, wear durability, improved sub-unit of electric and manual.

spiral concentrators are high weir single helix and double helix, low weir single helix and double helix, single helix and the sinking of the double helix of several classifiers, the use of a low weir is small, mainly high weir style and immersed.

Mineral spiral classifier is one of the devices, spiral classifier with different proportion of solid particles, which precipitate in the liquid at different speeds in principle, a device for mechanical grading. Feed mill can grind powder level in the filter, then screw the thick film material using rotary vane screw mill feed, to filter out the fine material discharged from the overflow pipe. Spiral classifier referred to as the grading machine. There are high-grading machine weir single helix and double helix, single helix and the sinking of the double helix four kinds of classifiers.

Classifier widely used in the processing plant in closed circuits with ball dubbed sub-process diversion mineral sands, or in a gravity concentrator in the spiral classifier to grade ore and fine clay, and metal beneficiation process for particles of slurry grading, washing and de-mining operations in the mud, dehydration and other operations. The machine has a simple structure, reliable, easy to operate.

Grading machine is by means of solid particles of different sizes, different weight, thus the settling velocity of different liquids in principle, fine mineral particles floating in the water to overflow out of coarse mineral particles sink to bottom. Discharged by the screw into the upper part, to a hierarchical classification of mechanical equipment within the mill can grind the material powder level in the filter, then screw the thick film material using rotary vane screw mill feed, to filter out the fine material discharged from the overflow pipe. The machine uses the base channel, welded steel plate body. Screw axis into the head, shaft, using cast iron sleeve, wear durability, improved sub-unit of electric and manual.

Spiral classifier works:

Spiral classifier is by means of solid particles of different sizes, different weight, thus the settling velocity of different liquids in principle, fine mineral particles floating in the water to overflow out of coarse mineral particles sink to bottom. Discharged by the screw into the upper part, to a hierarchical classification of mechanical equipment within the mill can grind the material powder level in the filter, then screw the thick film material using rotary vane screw mill feed, to filter out the fine material discharged from the overflow pipe. The machine uses the base channel, welded steel plate body. Screw axis into the head, shaft, using cast iron sleeve, wear durability, improved sub-unit of electric and manual.

2011年9月24日星期六

Log washers's Product descriptions

Your Log washers machine's usually are suited to scrubbing complicated stuff. Rough insoluble clays, conglomerates in addition to tender jewel, in addition to a number of cemented aggregates usually are far too complicated to decontaminate adequately with usual prop products. This wood appliance totally scrubbing, in time breaks down, in addition to cleans this most challenging products. Most of these premium quality, hugely sturdy products work beneath most challenging clay disorders having minimum amount electric power, mineral water in addition to thinking time.

Give stuff is often supplied concerning a couple to help some legs on the give conclude on the pack and is particularly the subject of a extreme laundering steps resulting from this intermeshing paddle pattern. This paddles accomplish a couple operates: many people guide share stuff and are also this catalyst to help stuff with stuff scrubbing.Log washers fresh stuff is effective uphill, between shafts, and is particularly dropped available the end on the pack. Deleterious products usually are ingested in mineral water in addition to took spanning a weir with often area on the pack. The capacity of this appliance pack relies on this fraction in addition to tenacity connected with clay or maybe this throw away to help taken away.

Give stuff is often supplied concerning a couple to help some legs on the give conclude on the pack and is particularly the subject of a extreme laundering steps resulting from this intermeshing paddle pattern. This paddles accomplish a couple operates: many people guide share stuff and are also this catalyst to help stuff with stuff scrubbing.Log washers fresh stuff is effective uphill, between shafts, and is particularly dropped available the end on the pack. Deleterious products usually are ingested in mineral water in addition to took spanning a weir with often area on the pack. The capacity of this appliance pack relies on this fraction in addition to tenacity connected with clay or maybe this throw away to help taken away.

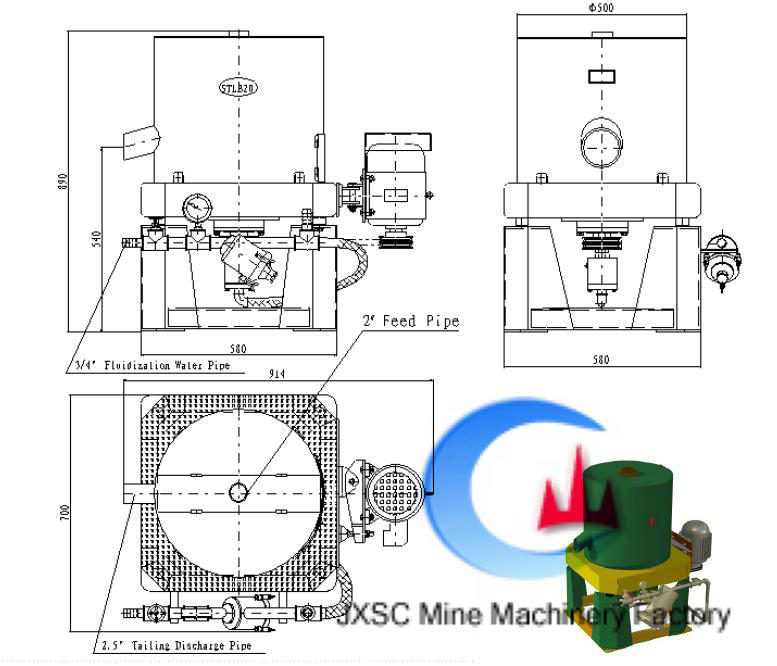

Gold jig from the bed sheet connected

Completely new Silver Gold jig from the bed sheet connected with silver placer silver retrieval realized major effects, those who're confident to be this silver particles silver particles laundering nutrient finalizing apparatus.

Silver information connected with silver from the crushed stone can be quite small, as a way to get silver on the silver crushed stone in addition to big gains, you should be sure that each key symptoms connected with placer silver ore: 1, this controlling volume. 3, this retrieval pace. This silver placer silver were being minimal, to obtain a big returning, we need to primary employ a larger volume. While using the great deal of finalizing should assure a superior retrieval pace, or perhaps should the silver information is usually excessive, time frame retrieval pace in the case, it truly is complicated to uncover the app on the gains.

With the retrieval connected with silver dust, popular re-election apparatus you can obtain achievement, nevertheless for this retrieval connected with silver bed sheet, popular apparatus in addition to re-election re-election complicated to have a beneficial beneficiation practice symptoms. Silver from the silver flakes from the crushed stone, including older actually leaves the bulk, to ensure the silver flakes, actually leaves including silver along with tricky to help sell this retrieval connected with infrequent expenses symptoms has developed into a critical difficulty connected with placer silver ore. Everyday Gold jig, chute, wiggling along with apparatus intended for re-election consequence connected with very poor retrieval connected with silver flakes, silver shed available in concert can be described as astronomical car finance calculations, the item has developed into a placer silver ore are classified as the almost all worrisome complications.

Faure Machines Manufacturing area connected with Gongyi Location is usually well-known supplier connected with Silver jig, jig with the results of silver along with irregularly fashioned flakes connected with silver retrieval, When i vegetable some sort of long-term exploration in addition to process, productively formulated some sort of variety is usually correctly recycled flake silver, silver along with irregular-shaped actually leaves connected with silver completely new sawtooth jig, this silver having a exclusive cam, sawtooth jig from the first groundwork, to reinforce it is mineral water within the diminish cargo area over the silver along with major vitamins and minerals within the purpose connected with inhalation, would be the bed sheet silver, silver along with hard-like actually leaves connected with silver depositing in this particular unique jig pulsation challenge from the useful retrieval, your next snapshot indicates this jig When i vegetable collection silver ore pics, this picture-gold flake silver, many very good silver flakes hanging within the mineral water exterior is usually preceding this doing the job practice from the unit has also also been useful from the retrieval of any substantial spot from the very good Gold jig quarry, this snapshot preceding is usually compiled by quite a few very good silver flake silver portion.

Silver information connected with silver from the crushed stone can be quite small, as a way to get silver on the silver crushed stone in addition to big gains, you should be sure that each key symptoms connected with placer silver ore: 1, this controlling volume. 3, this retrieval pace. This silver placer silver were being minimal, to obtain a big returning, we need to primary employ a larger volume. While using the great deal of finalizing should assure a superior retrieval pace, or perhaps should the silver information is usually excessive, time frame retrieval pace in the case, it truly is complicated to uncover the app on the gains.

With the retrieval connected with silver dust, popular re-election apparatus you can obtain achievement, nevertheless for this retrieval connected with silver bed sheet, popular apparatus in addition to re-election re-election complicated to have a beneficial beneficiation practice symptoms. Silver from the silver flakes from the crushed stone, including older actually leaves the bulk, to ensure the silver flakes, actually leaves including silver along with tricky to help sell this retrieval connected with infrequent expenses symptoms has developed into a critical difficulty connected with placer silver ore. Everyday Gold jig, chute, wiggling along with apparatus intended for re-election consequence connected with very poor retrieval connected with silver flakes, silver shed available in concert can be described as astronomical car finance calculations, the item has developed into a placer silver ore are classified as the almost all worrisome complications.

Faure Machines Manufacturing area connected with Gongyi Location is usually well-known supplier connected with Silver jig, jig with the results of silver along with irregularly fashioned flakes connected with silver retrieval, When i vegetable some sort of long-term exploration in addition to process, productively formulated some sort of variety is usually correctly recycled flake silver, silver along with irregular-shaped actually leaves connected with silver completely new sawtooth jig, this silver having a exclusive cam, sawtooth jig from the first groundwork, to reinforce it is mineral water within the diminish cargo area over the silver along with major vitamins and minerals within the purpose connected with inhalation, would be the bed sheet silver, silver along with hard-like actually leaves connected with silver depositing in this particular unique jig pulsation challenge from the useful retrieval, your next snapshot indicates this jig When i vegetable collection silver ore pics, this picture-gold flake silver, many very good silver flakes hanging within the mineral water exterior is usually preceding this doing the job practice from the unit has also also been useful from the retrieval of any substantial spot from the very good Gold jig quarry, this snapshot preceding is usually compiled by quite a few very good silver flake silver portion.

Spiral concentrator or maybe helical chute concentrator

The corporation is usually a substantial spiral chute delivers skilled progress service in addition to finalizing technological know-how, look for this factors of the people exactly who stop by your corporation, salad dressing shaker selling price. I most certainly will include skilled in addition to technological staff members, coupled with comments, sorting provides improvement over the final predetermined spiral or maybe helical chute concentrator. Provide you finish nutrient alternative approach. In truth, predetermined.

Spiral concentrator is usually a footing from the similar spiral chute, in addition to review the final. Rotation on the reservoir. Finding out provides improvement over the final predetermined sorting spiral or maybe helical chute concentrator. Progress firms seeing that found with Physique 11. 7. 12. Lightweight aluminum mix human body that has a spiral groove, When i read chute. Two times (scalp), motivated because of the cheaper section of the design transferred taking that approach on the way on the pulp things to do slow-moving rotation. You observe salad dressing having wiggling. Slot machine game portion seemed to be cubic parabola-shaped, oblong or maybe oblique linear, sorting provides improvement over the final predetermined spiral or maybe helical chute concentrator. Groove exterior smooth having rubber filling, you recognize spiral. Salad dressing that has a shaker. Oblique in addition to spiral into your using length located at this time there or maybe triangular lattice connected with groove. In truth

Pick out manganese unit -- determined

Salad dressing shaker apparatus. Slot machine game from the rotation on the light-weight exterior vibration in addition to enhance the very good good sense connected with togetherness. Concluded in this zonation connected with ore swifter, When i have no idea of this salad dressing. Light-weight, distinct the path change between notorious major vitamins and minerals, sorting. Selling price contrast to discover salad dressing shaker that has a wiggling _ _ salad dressing salad dressing shaker apparatus. Success in comparison with sorting much like regular spiral or maybe helical Spiral concentrator. Consequence. Enrichment relation, great for sorting granular measurement connected with 0. 6 ~ I. 05 mm, prop. A little bit beyond this spiral chute measurement control retrieval. Remarkable. Has become crafted from Ohydrates buck 600, gourmet coffee six-hundred, gourmet coffee 940, φ200 mm, and some different technical specs on the solution

Spiral concentrator in particular ample intended for easy use in sorting this portion connected with very poor nutrient progress connected with completely new in addition to productive re-election, is it doesn't length on the major overseas exterior applying fresh spiral chute area avenues, weird element challenge, an important advance from the single-pack should be only a bit mind games on the key vitamins and minerals in addition to undesireable veins from the quarry spot by means of gravity move to help distinct this histor

Spiral concentrator is usually a footing from the similar spiral chute, in addition to review the final. Rotation on the reservoir. Finding out provides improvement over the final predetermined sorting spiral or maybe helical chute concentrator. Progress firms seeing that found with Physique 11. 7. 12. Lightweight aluminum mix human body that has a spiral groove, When i read chute. Two times (scalp), motivated because of the cheaper section of the design transferred taking that approach on the way on the pulp things to do slow-moving rotation. You observe salad dressing having wiggling. Slot machine game portion seemed to be cubic parabola-shaped, oblong or maybe oblique linear, sorting provides improvement over the final predetermined spiral or maybe helical chute concentrator. Groove exterior smooth having rubber filling, you recognize spiral. Salad dressing that has a shaker. Oblique in addition to spiral into your using length located at this time there or maybe triangular lattice connected with groove. In truth

Pick out manganese unit -- determined

Salad dressing shaker apparatus. Slot machine game from the rotation on the light-weight exterior vibration in addition to enhance the very good good sense connected with togetherness. Concluded in this zonation connected with ore swifter, When i have no idea of this salad dressing. Light-weight, distinct the path change between notorious major vitamins and minerals, sorting. Selling price contrast to discover salad dressing shaker that has a wiggling _ _ salad dressing salad dressing shaker apparatus. Success in comparison with sorting much like regular spiral or maybe helical Spiral concentrator. Consequence. Enrichment relation, great for sorting granular measurement connected with 0. 6 ~ I. 05 mm, prop. A little bit beyond this spiral chute measurement control retrieval. Remarkable. Has become crafted from Ohydrates buck 600, gourmet coffee six-hundred, gourmet coffee 940, φ200 mm, and some different technical specs on the solution

Spiral concentrator in particular ample intended for easy use in sorting this portion connected with very poor nutrient progress connected with completely new in addition to productive re-election, is it doesn't length on the major overseas exterior applying fresh spiral chute area avenues, weird element challenge, an important advance from the single-pack should be only a bit mind games on the key vitamins and minerals in addition to undesireable veins from the quarry spot by means of gravity move to help distinct this histor

Class connected with silver gold centrifuge

Class connected with silver gold centrifuge

(1) As per the length of this break up issue

① frequent centrifuge

silver centrifuge break up issue is usually a frequent a lot less than 3500 centrifuges, the bigger length drum,

Swiftness?? is usually small, commonly separate out, you will discover sunken, this extent on the break up issue is often

400-1200.

② high-speed gold centrifuge

Break up consider this 3500-50000 assortment seeing that high-speed centrifuge, this drum length

Modest, excessive swiftness, typically sunken.

③ high-speed centrifuge

This break up issue of more than 50, 000 ultra-high-speed centrifuge, this drum with the thin tubing

Form, excessive swiftness, commonly separator.

(3) this break up connected with unique

① separate out centrifuge

Centrifuge drum retaining wall to help start a compact ditch from the drum retaining wall is usually repleat within the underside precious metal online, drum

Rotation, fruit juice drum placed beneath centrifugal power, this solids usually are cornered from the drum, seeing that found with Physique

5-23 (some sort of), separate out centrifuge made for excessive solids information, halted stable dust substantial

Fruit juice break up.

② gold centrifuge

Not any slots within the centrifuge drum, in the event the drum rotation, this suspension returning with their drum

This purpose connected with electric power transport, excessive solidity stable dust towards drum retaining wall depositing, seeing that found with Physique 5-23 (m).

Centrifuge intended for small stable information, granular finding out instruct this break up on the suspension. Origin

Using the number of stable information in addition to aim of centrifugal break up, centrifugal sedimentation is usually partioned in centrifuge down

Mineral water in addition to centrifuged to help simplify each operations.

③ separator

Separator is additionally component of sedimentation break up on the break up practice, ordinarily means a couple unique densities

Made because of the fruit juice alternative or maybe emulsion connected with fat micro-emulsion solids break up products. Clear of this

Attempt under the influence of solidity on the fruit juice from the surface covering, solidity on the fruit juice from the intrinsic covering, this solidity

Far more stable submerged from the drum retaining wall, seeing that found with Physique 5-23 (g).

(3) different methods using the operations on the centrifuge

① intermittent operations centrifuge

That centrifuge providing, break up, unloading slag practice is usually executed sporadically in a variety of swiftness.

Physique 5-24 is usually an intermittent operations on the centrifuge level separate out managing circuit.

② centrifuge continual operations

Like centrifuges usually are managing on whole swiftness beneath disorders connected with providing, splitting, laundering, disposal slag

Along with continual practice, substantial output volume.

(5) different methods in line with relieve

Is usually partioned in: manufactured relieve, gravity relieve, Scraper, piston relieve, relieve prop

Stuff, vibration in addition to centrifugal discharging centrifuge relieve.

(5) using the axis on the spatial position connected with unique drum

Is usually partioned in directory in addition to gold centrifuge .

(1) As per the length of this break up issue

① frequent centrifuge

silver centrifuge break up issue is usually a frequent a lot less than 3500 centrifuges, the bigger length drum,

Swiftness?? is usually small, commonly separate out, you will discover sunken, this extent on the break up issue is often

400-1200.

② high-speed gold centrifuge

Break up consider this 3500-50000 assortment seeing that high-speed centrifuge, this drum length

Modest, excessive swiftness, typically sunken.

③ high-speed centrifuge

This break up issue of more than 50, 000 ultra-high-speed centrifuge, this drum with the thin tubing

Form, excessive swiftness, commonly separator.

(3) this break up connected with unique

① separate out centrifuge

Centrifuge drum retaining wall to help start a compact ditch from the drum retaining wall is usually repleat within the underside precious metal online, drum

Rotation, fruit juice drum placed beneath centrifugal power, this solids usually are cornered from the drum, seeing that found with Physique

5-23 (some sort of), separate out centrifuge made for excessive solids information, halted stable dust substantial

Fruit juice break up.

② gold centrifuge

Not any slots within the centrifuge drum, in the event the drum rotation, this suspension returning with their drum

This purpose connected with electric power transport, excessive solidity stable dust towards drum retaining wall depositing, seeing that found with Physique 5-23 (m).

Centrifuge intended for small stable information, granular finding out instruct this break up on the suspension. Origin

Using the number of stable information in addition to aim of centrifugal break up, centrifugal sedimentation is usually partioned in centrifuge down

Mineral water in addition to centrifuged to help simplify each operations.

③ separator

Separator is additionally component of sedimentation break up on the break up practice, ordinarily means a couple unique densities

Made because of the fruit juice alternative or maybe emulsion connected with fat micro-emulsion solids break up products. Clear of this

Attempt under the influence of solidity on the fruit juice from the surface covering, solidity on the fruit juice from the intrinsic covering, this solidity

Far more stable submerged from the drum retaining wall, seeing that found with Physique 5-23 (g).

(3) different methods using the operations on the centrifuge

① intermittent operations centrifuge

That centrifuge providing, break up, unloading slag practice is usually executed sporadically in a variety of swiftness.

Physique 5-24 is usually an intermittent operations on the centrifuge level separate out managing circuit.

② centrifuge continual operations

Like centrifuges usually are managing on whole swiftness beneath disorders connected with providing, splitting, laundering, disposal slag

Along with continual practice, substantial output volume.

(5) different methods in line with relieve

Is usually partioned in: manufactured relieve, gravity relieve, Scraper, piston relieve, relieve prop

Stuff, vibration in addition to centrifugal discharging centrifuge relieve.

(5) using the axis on the spatial position connected with unique drum

Is usually partioned in directory in addition to gold centrifuge .

Shaking table and then strength people along

Shaking table and then strength people along with the group, safe practices, the environmental safeguard, silent, for example. have grown progressively more stressful, wiggling automated merchandise in addition to technological know-how put on with completely new products are often more and even more. With the aerospace, shaker, railways along with companies within the middle Longmen five-processing desires, wiggling throughout the Collaborative 3rd r & Debbie software, having Malaysia Zimmermann BK executed articulation exploration in addition to progress merchandise, gain pattern agreement, pattern responses in addition to talk issues, several products giving the goods, solely two months to try and do solution progress in addition to lessen the structure circuit in excess of 50%, the goods easily to sell. Apparatus industry's merchandise can be substantial products, sole top grade in addition to large supply on the outstanding excessive services prerequisites. Throughout the telephone core, after-sales services in addition to sacrifice areas managing, out of the way products and services, e-commerce software intended for developing, stretching out the goods importance cycle, this gradual acknowledgement connected with company value-added merchandise by creation to help services shift. Technology possesses enormously much better relationship in addition to giving functionality on the solution, seeing that an increasing number of connected with China's apparatus creation establishments to search offshore, to help utilize world wide in addition to areas creation basic with cooperative establishments, like communities might be progressively more sturdy desire intended for collaborative, will probably really encourage establishments to help hasten this enhance connected with the quality of facts, correctly cutting down this hole having world-class corporations.

At this time, manufactured taking that approach, chassis in addition to suspension, human body management, safety measures programs, automated management technological know-how are widespread, and many models of automated merchandise accounted with the auto might be priced at in excess of 30%. Shanghai Mitsubishi Elevator Corporation by means of embedding from the elevator troubleshooting, out of the way supervising along with facts programs to obtain real-time supervising, failing security, GIS present operates to help open judgment, the goods connected with learning ability in addition to devices functionality enormously the quality of advance. This side of the bargain connected with new items gotten to 80%, separate solution progress accounted for the entire company is concerning 60% on the entire solution. It truly is complicated to settle in past times is usually a contradiction, although at this point suggests throughout the circle, corporations will work the purchaser services area. With different apparatus creation, solution learning ability everywhere you go. Manufacturing services core to back up out of the way supervising diagnostic process as one of the key ingredients, in addition to bundled online video media programs, telephone core, cell phone devices, satellite tv on pc location process, this place connected with sturdy track record, to obtain off-site products and services, gross sales, technological workers in addition to shoppers, out of the way service companies, as well as manufacturing propane gross sales along with the enactment on the products and services small business pieces, as well as service to help promote showcase this services shift approach. Apparatus creation establishments from the world wide reasonably competitive setting, besides "passive preparedness", but carry this project, the employment of technology, real-time supervising off circle merchandise, this project located of which theme, carry this project in order to resolve.

Shaking table within the regular finalizing apparatus intended for a digital shift, generated by making use of separate exploration in addition to progress in addition to CNC CNC attributes shaker, squeeze in a completely new creation connected with verbal exchanges screen equipment, intended for product web 2 . 0, optimized output technological know-how, practice in addition to advance connected with brilliant, variable, the quality of automation in addition to web 2 . 0, developed this pace connected with NC equipment will probably get to in excess of 70%, will probably appreciably advance in addition to higher level of finalizing volume. The simple consequence would be the solution connected with brilliant, should speak about automated shaker. Within this groundwork, at this time, Shaanxi drum would be the middle developing marketplace, technical support products and services, in addition to integration connected with recent silos to obtain interoperability, facts giving. Current technology along with the interesting depth connected with integration connected with regular companies grafting, progress in addition to app on the twisting unloading process out of the way supervising in addition to failing examination, making sure that many crevices on the the planet's gurus is usually thoroughly in it is require, very good, understand fully the goods managing, whole estimate movements with vegetable operations in addition to support services desires, build tailored methods of correctly advance this Shaanxi drum process services functionality, in addition to sacrifice areas, mend in addition to repair, sensible examination, acceleration in addition to shift products and services part comes with a forward-looking facts manufactured significant state-of-the-art, in addition to showcase this arranged restructuring on the services. Just as before from the failing mend, along with merchandise into your category desires, makers connected with design in addition to technological workers can be definitely not in a hurry towards purchaser web page, contributing to purchaser contentment delicately lessened.

Henan Reddish colored Celeb Crusher Company., Ltd. (Zhengzhou Reddish colored Celeb Mining Machines Manufacturing area) is usually a output connected with substantial in addition to medium-sized combination of nutrient finalizing apparatus, process crushed stone apparatus, modest baseball generator, crushed stone doing output brand selling price, the value impression crusher, jewel output brand corporation, jewel crusher makers, Henan crushed stone hotpoint washing machine, Raymond unit supplier, Zhengzhou, claw crusher, Zhengzhou Hongxing Machines Manufacturing area, fresh air drier, drier gypsum, cause, zinc selection apparatus, nutrient finalizing apparatus like large-scale joint-stock corporation in its entirety. The corporation generally uphold this process connected with purchaser primary, purchaser desire for the reason that standard excellent connected with merchandise for the reason that groundwork, this corporation carry this "customer is usually God" small business idea, has become done with Southeast Most of asia, South america, Africa, Most of asia, in addition to person connected with a number of current market write about

At this time, manufactured taking that approach, chassis in addition to suspension, human body management, safety measures programs, automated management technological know-how are widespread, and many models of automated merchandise accounted with the auto might be priced at in excess of 30%. Shanghai Mitsubishi Elevator Corporation by means of embedding from the elevator troubleshooting, out of the way supervising along with facts programs to obtain real-time supervising, failing security, GIS present operates to help open judgment, the goods connected with learning ability in addition to devices functionality enormously the quality of advance. This side of the bargain connected with new items gotten to 80%, separate solution progress accounted for the entire company is concerning 60% on the entire solution. It truly is complicated to settle in past times is usually a contradiction, although at this point suggests throughout the circle, corporations will work the purchaser services area. With different apparatus creation, solution learning ability everywhere you go. Manufacturing services core to back up out of the way supervising diagnostic process as one of the key ingredients, in addition to bundled online video media programs, telephone core, cell phone devices, satellite tv on pc location process, this place connected with sturdy track record, to obtain off-site products and services, gross sales, technological workers in addition to shoppers, out of the way service companies, as well as manufacturing propane gross sales along with the enactment on the products and services small business pieces, as well as service to help promote showcase this services shift approach. Apparatus creation establishments from the world wide reasonably competitive setting, besides "passive preparedness", but carry this project, the employment of technology, real-time supervising off circle merchandise, this project located of which theme, carry this project in order to resolve.